One of the invaluable lessons my dad passed down was the importance of sharp tools. That being said, my dad was not very good at sharpening tools and frankly, neither was I. Dad’s logic was that dull tools require more effort to make cuts and more effort meant loss of control. Loss of control leads to injuries, such as a severed tendon on my left index knuckle. Many years ago dad bought a Makita Wet Sharpening System for his new Grizzly Planer. The Makita was a fine system, but it still required a certain degree of art to sharpen tools on it and the water was always a downside. Repairing a damaged tool was not an option for the Makita, it was meant for fine honing only. Recently, a Work Sharp 3000 came my way for a review and I have to say, I have fallen in love with it.

The WorkSharp 3000 is adry system and like my Makita, it has the topside tool rest, but it also has a port underneath the abrasive wheel for sharpening woodworking tools to common angles. It is the port that I truly love. I am a novice woodworker and more of a novice at sharpening my tools. But Worksharp has made this irrelevant. I took several new Stanley wood chisels I picked up at Lowe’s for a project we were working on. Now the chisels came from the rack pretty sharp. But in reading the manual on the Worksharp 3000 it advised sharpening new tools also. So I decided to sharpen my 1.5″ chisel and see those results before tackling the smaller ones.

The process was simple. Lap the flat side of the chisel starting with coarse abrasive disc and working to the finest abrasive, 3600 grit. Immediately the difference in the finish was apparent. By the second abrasive, the flat side was beginning to have a mirror-like finish. After the 3600 grit, the reflection was unbelievable. The smoothness of the metal I would have expected from a wet wheel with fine abrasive. But on the Worksharp, I spent maybe 10 minutes to achieve this flat mirror finish. Quickly I did the other three new chisels, the one inch, the .75 inch, along with the .5 inch.

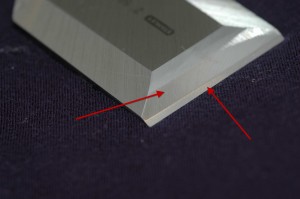

The next step I put thought into. What angle should I set the chisel port to, 20,25 or 30 degrees? I settled on a 25 degree for the main angle and a 30 degree for my micro bevel. I adjusted the port by simpling grasping the lever and pulling up until the dial read 25 degrees. I set the port guide for my 1.5 inch chisel by adjusting the fence until it was close enough to the chisel edge to prevent angle change, yet loose enough for the chisel to not bind on the fence when I pushed the chisel into the disc. Starting with the coarse disc, I ground until I had a uniform face on the bevel side of the chisel. This is easy to see even on a new chisel. Once I had the initial grind, I moved the fence to accept the narrower chisels and repeated the process, 25 degrees on all four. After I had the face uniform, I began to work through the abrasives, changing the discs to finer abrasives after finishing all four. The process went quick. Starting off with the widest chisel and working my way until I had finished the narrowest chisel and then changing the disc to a finer abrasive, then I would start with the 1/2 inch chisel and work my way back out to the widest chisel, changing the fence to accept each width. The by merely reversing the process from wide to narrow and changing to a finer abrasive with each cycle. Upon finishing with the 3600 grit, the chisel cutting surfaces looked like mirrors with no visible scratches. I could have stopped here and used the tools as single bevel 25 degree chisels, but I opted to add a micro bevel.

The micro bevel adds a second angle that becomes the working edge and only changes the angle on a small part of the cutting edge. By adding a 30 degree micro bevel, resharpening takes less time and the 30 degree angle should stay sharp longer than the 25 degree bevel. I laid each of the tools on my arm and checked for sharpness by shaving hair. With little force, each of the chisels made forearm hair disappear like a straight razor had been run across it. In actual use the chisels, could now shave wood with very little effort and tool control was remarkably enhanced. Dad was right. These chisels may be sharp, but they also glide into the wood with little effort. Less effort means less likelihood of a chisel slipping from a workpiece and cutting its user.

The Work Sharp 3000 would make an excellent addition to any woodworker’s shop. A novice woodworker would benefit by having the luxury of always having sharp tools without the use of stones or wet wheels and for the more experienced woodworker, the 3000 accepts readily available abrasive discs available at most home improvement centers and woodworking stores. I am not throwing my wet system out, merely moving it farther back on the workbench as the Worksharp 3000 can handle everyday sharpening much more efficiently. Lathe tools and larger tools can be sharpened on the top side of the disc. The 3000 includes slotted disc that allow visibility of the tool being sharpened on the underside of the disc from above.

If you are like me and have a lot of older chisels needing repair, the 3000 makes regrinding damaged chisels an easy task. Use the coarse abrasive until the bevel is once again uniform, and any nicks are removed, then work through the finer abrasives until the tool is restored to sharpness. The speed of the wheel is such that excessive heat build up in your older tools should not be an issue.

I would like to try the knife sharpener system from Work Sharp. If it handles knife sharpening as readily as the 3000 handles chisels and plane blades, it too should be a winner.