Have you ever used a circular saw blade backwards? For most jobs it’s a terrible idea and very dangerous. But for a certain few materials, it’s a smart way to make a smooth cut.

This tool tip was inspired by a recent question from an EHT reader: “What’s a good method for cutting aluminum gutter material?”

One basic method is to clamp the gutter material firmly to a couple of saw horses and cut using a hacksaw. A good pair of metal snips can also do the job.

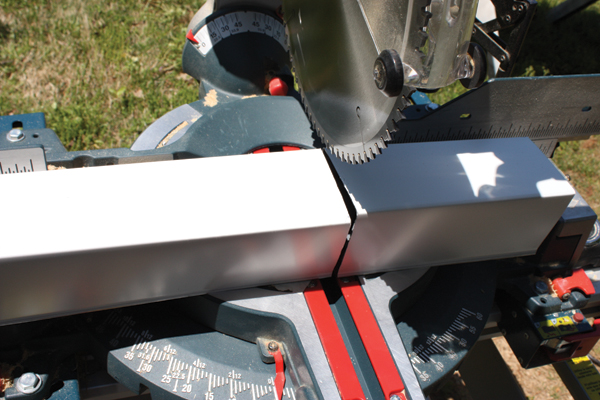

Either of those methods works fine, but I prefer using a sliding miter saw with a fine-toothed blade mounted backwards. The speed of the blade combined with the backward teeth make a nice, clean cut with very little operator effort, and without the teeth tearing out and distorting the metal. Note: When cutting gutter material on the miter saw, turn the profile upside-down so the cut enters the more stable underside of the gutter rather than the top edges.

But that’s not the only use of a backwards circular blade. It’s also great trick for rough-cutting plastic laminate for countertops. I use a fine-tooth blade installed backwards in a table saw. Place a strip of masking tape where the cut is to be made to make the line easier to see. Set the blade depth so the teeth just barely extend past the cutting surface. The rip guide of the table saw helps to control a straight cut, and although the cutting process takes longer with the blade on backwards, the cut is perfect. In fact, the blade simply peels away a strip of the material in a ribbon that’s as wide as the kerf of the blade, and the cuts are perfectly smooth. Granted, you’ll need to set up both outfeed and lateral supports to work with the big 4×8′ sheets, but I find this to be a great way to make accurate cuts.

One more use for a backwards circ saw blade: Vinyl siding. When cutting vinyl siding with a circular saw, install a fine-toothed blade backwards on the saw for a smoother, cleaner cut, especially in cold weather (when the material is brittle). Make the cut slowly.

Having said all this, let me now emphasize that you should NEVER cut anything else with the blade on backwards other than what I’ve explained here. So, once you’ve finished with the backward blade, immediately take it off and re-install it in the conventional manner. Safety first!

— M. Weber